By default, Ordermation numbers the groups of products that are combined on one shop traveler document in the order in which they are processed. The order in which products are processed can be controlled by adjusting the GROUPING QUERIES. The GROUPING QUERIES are used to select products with similar enough properties to be represented on the same shop traveler from the opening schedule.

There are cases were a different numbering system is desired.

For example, a customer does not want different line items to be combined into groups. The customer wants each line to be in its own group and have its own assembly traveler sheet.

Since each line item has its own sequence number, we can create the desired grouping by keying on this property in the GROUPING QUERIES (See details at the end of this post)

These commands result in each line item being its own group, and the groups being

processed in the order of the line items. So, if we process an entire release of just doors or

just frames, the group numbers are as desired.

But suppose we process just a subset of line items. For example, if we process just line item

6. The group number will be 1, because we are only processing 1 group and they are

numbered in order.

By setting the SYSTEM SETTING: “GROUP_NUMBER_OVERRIDE” to the expression: “+FSTR(+VOSchedLineNumber)”, we can force the group number to be the same as the line item sequence number.

Then when we process just line 6:

The release status indicates we are starting with sheet 6:

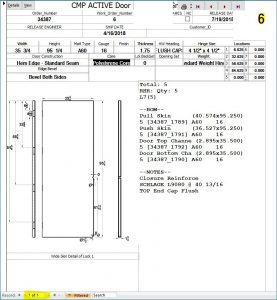

And the resulting assembly sheet is numbered 6:

The GROUPING QUERIES used in this example:

FRAME_GROUP

SELECT OrderForm.OSchedLineNumber, OrderFormLineItem.OrderFormLineItemFrameRelease, OpenScheduleSheet.OpenScheduleSheet_JobID

FROM (REL_OrderFormLineItemID LEFT JOIN ((OrderForm RIGHT JOIN OrderFormLineItem ON OrderForm.OrderFormID = OrderFormLineItem.OrderFormID) LEFT JOIN OpenScheduleSheet ON OrderForm.OrderForm_OpenScheduleSheetID = OpenScheduleSheet.OpenScheduleSheetID) ON REL_OrderFormLineItemID.r_OrderFormLineItemID = OrderFormLineItem.OrderFormLineItemID) LEFT JOIN OrderFormNumeric ON OrderForm.OrderFormID = OrderFormNumeric.OFN_OrderFormID

WHERE (((OrderForm.Frame_ElevInJobID)<>0) AND ((OrderFormLineItem.OrderFormLineItemSkipFrame)=False))

GROUP BY OrderForm.OSchedLineNumber, OrderFormLineItem.OrderFormLineItemFrameRelease, OpenScheduleSheet.OpenScheduleSheet_JobID

ORDER BY OrderForm.OSchedLineNumber;

LEAF1_GROUP

SELECT OrderForm.OSchedLineNumber, OrderFormLineItem.OrderFormLineItemDoorRelease, OpenScheduleSheet.OpenScheduleSheet_JobID

FROM (REL_OrderFormLineItemID LEFT JOIN ((OrderForm RIGHT JOIN OrderFormLineItem ON OrderForm.OrderFormID = OrderFormLineItem.OrderFormID) LEFT JOIN OpenScheduleSheet ON OrderForm.OrderForm_OpenScheduleSheetID = OpenScheduleSheet.OpenScheduleSheetID) ON REL_OrderFormLineItemID.r_OrderFormLineItemID = OrderFormLineItem.OrderFormLineItemID) LEFT JOIN OrderFormNumeric ON OrderForm.OrderFormID = OrderFormNumeric.OFN_OrderFormID

WHERE (((OrderForm.Door_ElevInJobID)<>0) AND ((OrderFormLineItem.OrderFormLineItemSkipFrame)=False))

GROUP BY OrderForm.OSchedLineNumber, OrderFormLineItem.OrderFormLineItemDoorRelease, OpenScheduleSheet.OpenScheduleSheet_JobID

ORDER BY OrderForm.OSchedLineNumber;

LEAF2_GROUP

SELECT OrderForm.OSchedLineNumber, OrderFormLineItem.OrderFormLineItemDoorRelease, OpenScheduleSheet.OpenScheduleSheet_JobID

FROM (REL_OrderFormLineItemID LEFT JOIN ((OrderForm RIGHT JOIN OrderFormLineItem ON OrderForm.OrderFormID = OrderFormLineItem.OrderFormID) LEFT JOIN OpenScheduleSheet ON OrderForm.OrderForm_OpenScheduleSheetID = OpenScheduleSheet.OpenScheduleSheetID) ON REL_OrderFormLineItemID.r_OrderFormLineItemID = OrderFormLineItem.OrderFormLineItemID) LEFT JOIN OrderFormNumeric ON OrderForm.OrderFormID = OrderFormNumeric.OFN_OrderFormID

WHERE (((OrderForm.Leaf2_ElevInJobID)<>0) AND ((OrderFormLineItem.OrderFormLineItemSkipFrame)=False))

GROUP BY OrderForm.OSchedLineNumber, OrderFormLineItem.OrderFormLineItemDoorRelease, OpenScheduleSheet.OpenScheduleSheet_JobID ORDER BY OrderForm.OSchedLineNumber