Sticks with multiple hardware Rabbets

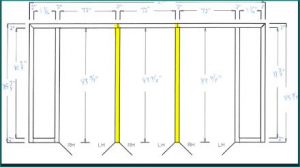

Elevations that require hardware preps to be placed on more than one rabbet include communicating frames in which a door is placed on both sides of a double rabbet jamb, and frames with multiple door openings where a mullion has doors both to the left and to the right, as in the elevation with the double sided mullions pictured blow:

Automatic Tooling With Custom Shapes

The Digital Resources System is designed to tool parts completely automatically, even when the use of custom tooling shapes is required. The system can be trained to use any arbitrary shape appropriately.

Here we see an overview of a hinge jamb produced in a turret with limited tooling including very custom shapes.

Three special cases are show. A special miter tool used to punch the miter and a portion of the rabbet. This tool is asymmetrical and its center is offset, yet it is automatically used exactly as desired. A special tab tool is used to punch the complete tab and a portion of the base lines. And, due to limited tooling, a round hit is used to approximate the 45 degree chamfer.

The use of these special tools, and the jagged shape of the area being punched, leaves a scrap remnant whose odd shape is handled efficiently by the system’s scrap removal.

Using all tools on one edge before using them on the other

In a turret punch press, it is often fastest to make all hits with a given tool before changing to another tool. There are circumstances where it is necessary to override that behavior, such as when rapid travel from one edge of a long part to the other could dislodge a piece of scrap held on by micro-joints.

In the Digital Resources’ system, all tooling is done completely automatically. This example shows how we set up a rule for detecting when this tooling order is needed, along with a rule for applying the tooling order.